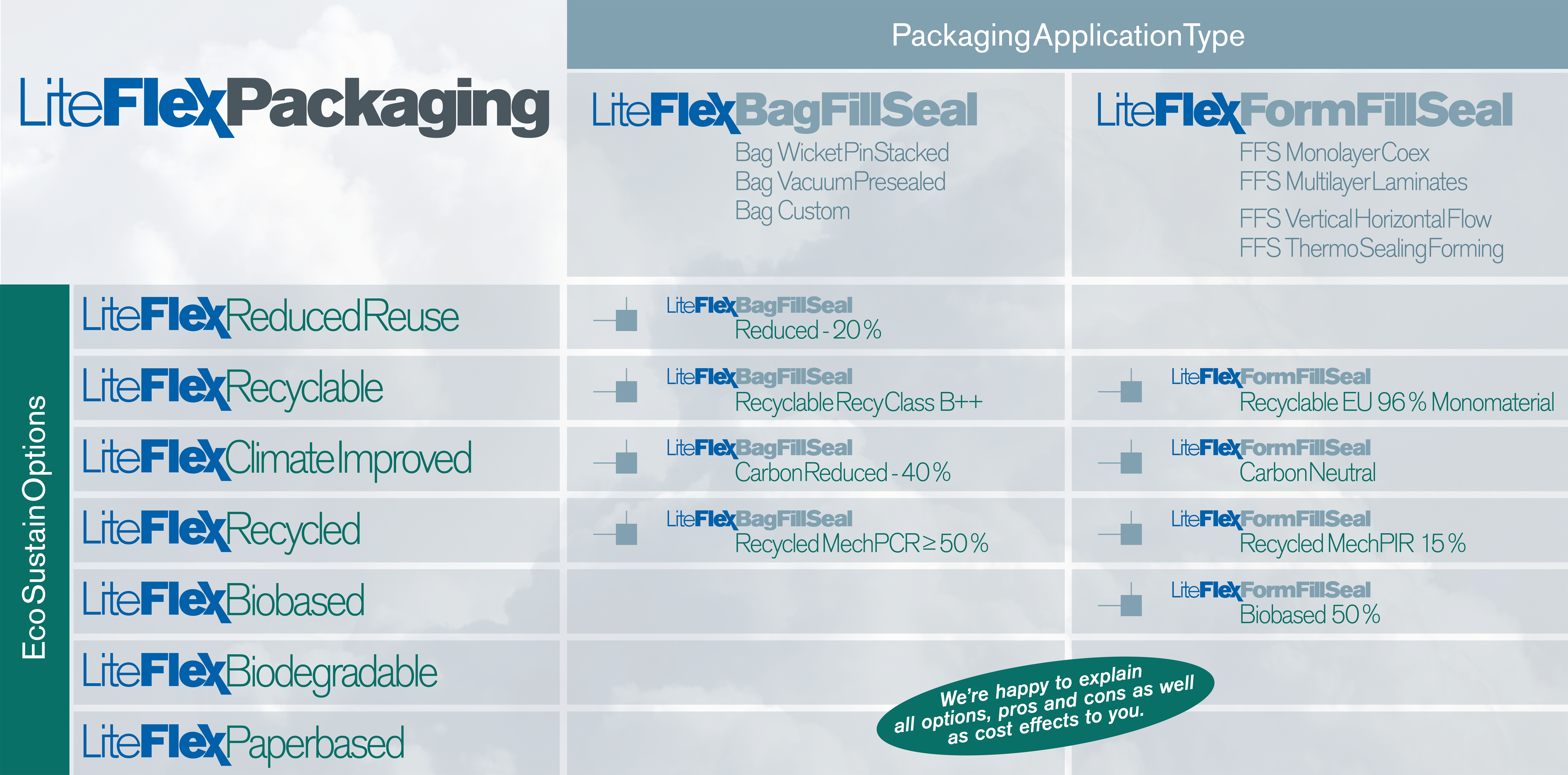

We produce LiteFlexPackaging as pre-assembled bags (LiteFlexBag) or as rolls that are formed, filled and sealed during an automated process at our customers’ site. (LiteFlexFormFillSeal).

We are happy to explain the numerous possible combinations for application and sustainability.

Examples are shown here:

- A bag made with 20% less material compared to the previous version and at least 50% made from PostConsumer-recyclate. This way, the ProductCarbonFootprint (based on ISO 14067) can be reduced by 40%. When applying the RecyClass standard, it achieves a high recyclability of B ++. In order to be correct, we pay attention to the details: Do we talk about Cradle-to-gate or the entire life cycle, according to which standard should the recyclability be assessed?

- Another example: In the right FFS column, we achieve a climate-neutral ProductCarbonFootprint by using mainly biobased raw materials. The high percentage of recyclability (e.g. in accordance with the German Mindeststandard, additionally tested for the entire EU) is made possible by a mono-material composition.

- Incidentally, there are several variants of recyclates: mechanical, solvent-based or chemical as well as the feedstock options PIR (Post Industrial) and PCR (Post Consumer), the latter also of different origins: PostCommercial, PostHousehold, PostOceanWaste.

- Complicated? We’re happy to consult and provide you with tailormade solutions